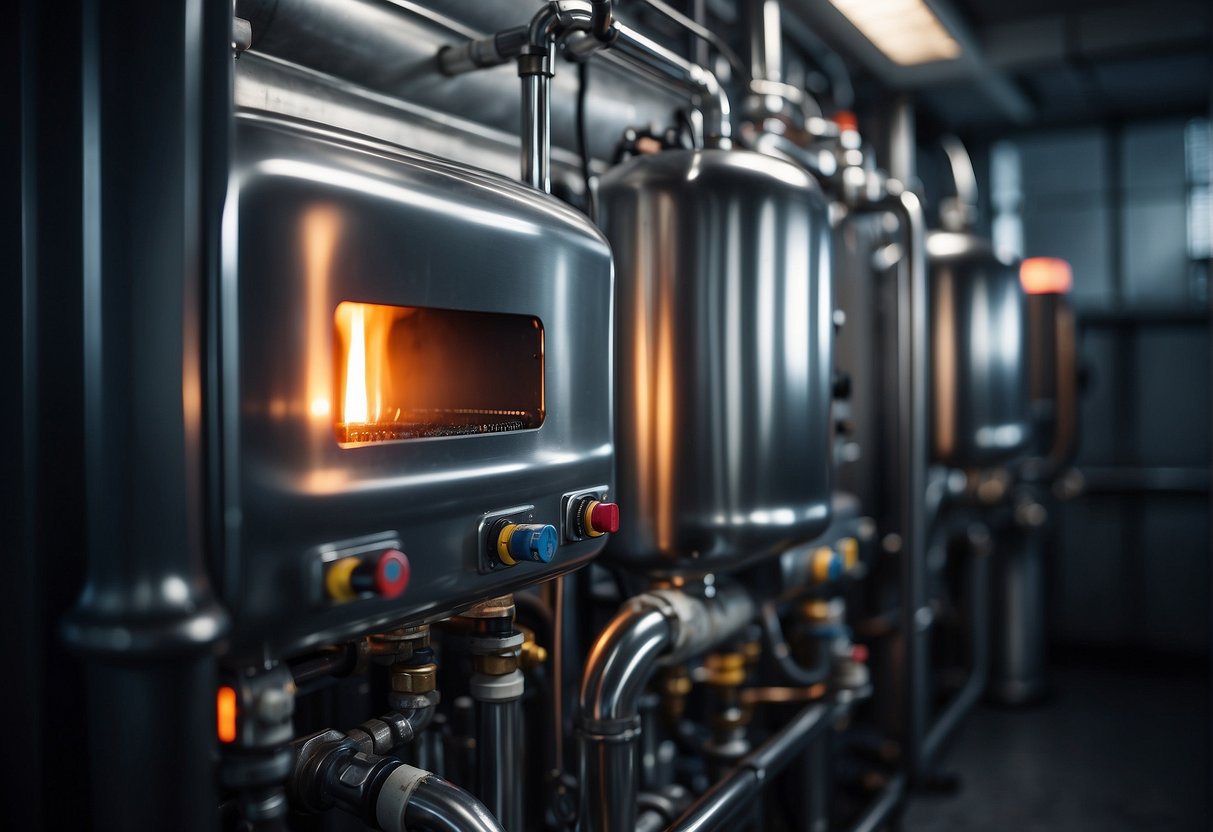

Gas boilers are a fundamental necessity in numerous UK households, ensuring the provision of hot water and central heating to create a cozy and welcoming environment.

Understanding the key components of a gas boiler system is crucial for homeowners to appreciate how their heating systems work.

The components are the burner, which makes the heat, the heat exchanger, which moves heat to the water, and the controls, which manage the system.

If you have problems with your gas boiler components, contact our Ashford boiler installers for a quick and professional resolution.

While the basic operation of a gas boiler might seem straightforward, there’s a complex interplay of parts working behind the scenes to ensure efficient functioning.

For instance, boilers include safety devices that monitor pressure and temperature to avoid accidents. Regular maintenance is essential, as it ensures that all the elements of the boiler, from the pump to the thermostat, operate effectively and safely.

Troubleshooting any issues that arise with these systems often requires professional attention, although some frequently asked questions can be addressed by the homeowners themselves with a bit of knowledge.

Key Takeaways

- Gas boilers provide essential heating and hot water in UK homes through a series of interconnected components.

- Routine maintenance is key to ensuring the safe and efficient operation of a gas boiler.

- The complex functionality of gas boilers necessitates professional attention for troubleshooting and repairs.

Basic Understanding of a Gas Boiler

A gas boiler is a vital component of many UK homes, providing both central heating and hot water. They operate by burning natural gas to heat water, which is then distributed through the home via radiators or used directly from taps.

Components and Functions

Burner: This is where the natural gas is ignited, producing heat in the process.

Heat Exchanger: Transfers heat from the burner to the water within the system.

Control System: Manages the ignition and operation of the burner to maintain desired temperatures.

Pump: Circulates water through the central heating system.

Thermostat: Senses room temperature and communicates with the boiler to turn on or off to maintain the desired temperature.

Expansion Vessel: Compensates for the increase in water volume as it heats up.

Safety Valve and Pressure Gauge: Ensures the system remains within safe operating pressures.

Types of Gas Boilers

Combi Boilers: Compact units that provide both central heating and instantaneous hot water without the need for a separate storage tank.

System Boilers: Require a cylinder for storing hot water, but all the main components are built into the boiler.

Regular Boilers: Work with a separate cold water tank and hot water storage tank, suitable for homes with multiple bathrooms.

Boiler Types Compatible with Renewable Energy: Some system and regular boilers are compatible with solar water heating systems for a more sustainable and efficient home energy solution.

Core Elements of Gas Boiler Operation

In understanding gas boiler efficiency and safety, one must consider the critical components that ensure its proper functioning. These include the combustion chamber, heat exchange mechanism, and intricate control systems.

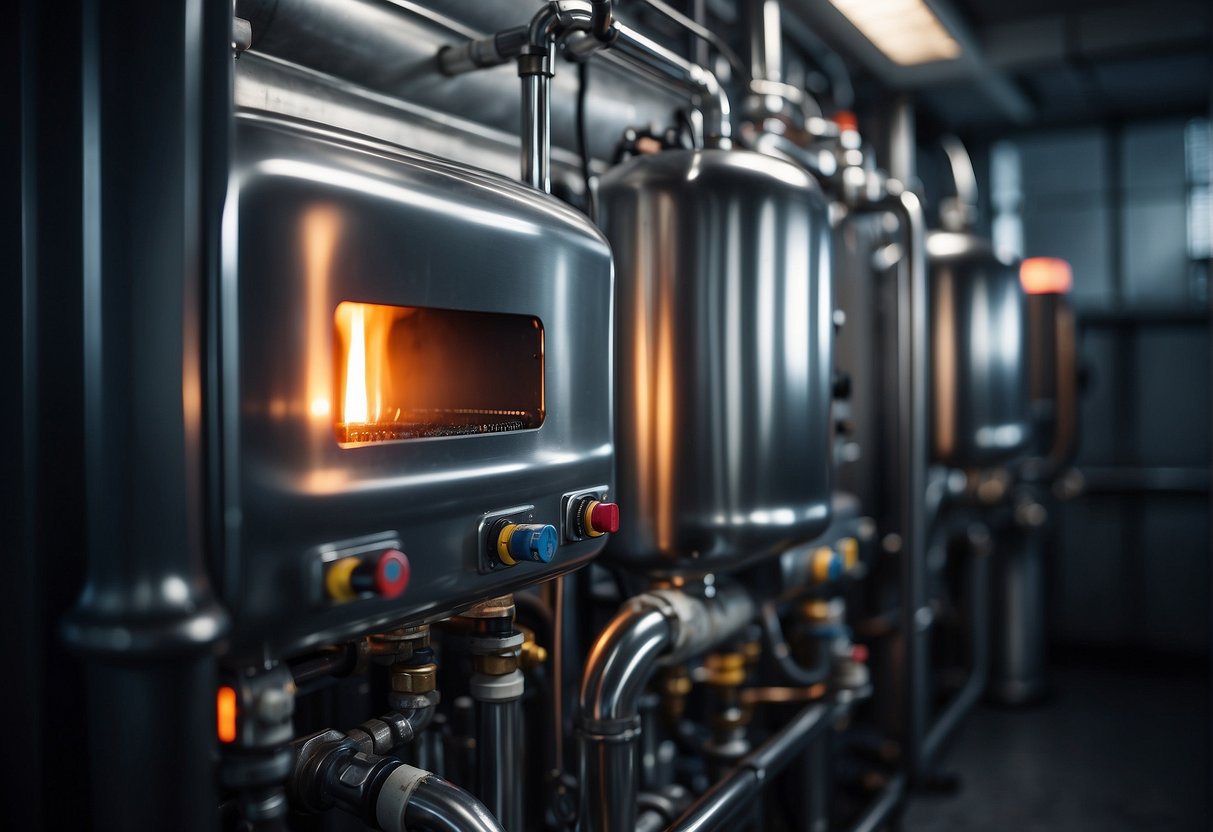

Combustion Chamber and Heat Exchange

The heart of a gas boiler lies in its combustion chamber, where the burner ignites the gas to produce heat. It’s here that the chemical energy of the gas is converted into heat energy.

The heat exchanger then serves as a bridge that transfers this heat to the water circulating within the system. The exchanger must preserve the efficiency of heat transfer to maintain the ideal operation temperature and energy use.

Regulation and Control Systems

Boiler controls are pivotal in managing the heat production and distribution. The thermostat gauges the temperature and signals the boiler to initiate or halt heating. Valves play a critical role in directing the flow of hot water or steam.

The control system is engineered to maintain optimal functioning, adjusting the burner operation to match the heat demand, thus ensuring efficiency and safety.

Expansion and Distribution

As the heated water expands, the expansion tank prevents excessive pressure build-up within the boiler system. Having ample space for the water to expand is crucial for maintaining system integrity.

The pump ensures that the heated water is circulated through the distribution system to radiators or taps throughout the property. A safety valve is also integral to protect the system from reaching unsafe pressure levels.

Each component’s seamless interaction guarantees that the warmth generated by the gas boiler reaches every part of the home efficiently and safely, adhering to UK standards and practices.

Efficiency and Safety Features

In the realm of gas boilers, it’s vital to balance energy efficiency with rigorous safety standards to ensure both reduced energy bills and protection from potential hazards like carbon monoxide leaks. Each component within the boiler plays a critical role in maintaining this equilibrium.

Enhancing Energy Efficiency

Energy efficiency in boilers is paramount for minimising energy bills and reducing one’s carbon footprint. The implementation of condensing boilers has been a significant advancement in this area. These boilers are designed to capture heat that would otherwise escape through the flue gases and reuse it, thereby operating at an efficiency level of over 90%. Modern units often incorporate a Lambda Pro Control system, adjusting the gas and air mixture for optimal combustion at all times, further enhancing efficiency and leading to lower fuel consumption.

For homes utilising sustainable resources, biomass boilers burn organic materials, delivering a more environmentally friendly solution. They are highly efficient and a renewable option for homeowners aiming to reduce their reliance on fossil fuels.

Safety and Maintenance Requirements

The safety of boiler operation hinges on proper maintenance and the integration of several key components. Safety valves act as a fail-safe, releasing pressure if it becomes too high. Regular servicing is imperative to check these and other components like the heat exchanger and burner, to prevent problems like gas leaks.

An essential aspect in the safety array is the carbon monoxide detector. It is crucial in every household or building with a gas boiler, as carbon monoxide is an odourless and colourless gas that can lead to severe health risks if leaked. It’s important to regularly check and maintain these detectors to ensure they are functioning correctly.

Thorough maintenance not only ensures the safety of the boiler but also contributes to maintaining its energy efficiency. An annual inspection by a qualified engineer is recommended to keep the boiler in top condition and operating safely. This helps in the early detection of any potential faults, safeguarding the system against breakdowns and potentially dangerous situations.

Troubleshooting and Repair

When tackling gas boiler repairs, it’s essential to first understand the most common issues and their potential fixes. Diagnostics can identify whether a problem stems from faulty thermostats, a stuck valve, leaky pipes, or a malfunctioning circulator pump.

- Thermostats: If heating is erratic, check that the thermostat is correctly set and operational. It may need recalibration or battery replacement.

- Valves: A boiler’s pressure issues can often be traced to the valve. Should the valve be seized or stuck, a service professional must examine it to determine if repair or replacement is necessary.

- Leaks: Detecting leaks in pipes requires a close inspection of all connections and joints for indications of water or gas leaks, as these can lead to drop in pressure or dangerous situations.

- Pumps: The circulator pump might require resetting, or if it’s notably noisy, it may indicate blockage or impending failure.

Regular maintenance is crucial, as it can thwart the development of these common issues. Service professionals should be called for major faults or when in doubt of the repair’s complexity. They come equipped with the proper diagnostics tools to ensure a safe and effective return to function.

As part of an ongoing maintenance strategy, homeowners can regularly bleed radiators to remove air and maintain efficient heating or monitor the boiler pressure, making small adjustments as required.

For specific troubleshooting, manufacturers’ guides and professional advice are indispensable. They can provide tailored instructions and safety precautions for issues unique to each brand or model. A qualified engineer should always handle repairs beyond the scope of routine homeowner maintenance, ensuring compliance with UK regulations and safety standards.

Frequently Asked Questions

This section provides clear answers to common inquiries concerning the inner workings of gas boilers, detailing key components and their functions.

What are the essential components found in a typical gas boiler?

A typical gas boiler comprises several critical components such as a gas burner, heat exchanger, flue, thermostat, controls, safety valve, and a pump. These parts contribute to the effective heating and regulation of water or space heating in a property.

How do the primary parts of a gas boiler operate together?

In a gas boiler, the gas burner produces heat which is then transferred to water or a heat-carrier fluid via the heat exchanger. The pump circulates this heated fluid throughout the system, and the control unit manages the operating temperature and ensures efficient functioning.

Could you explain the role of the heat exchanger in gas boilers?

The heat exchanger is a vital component in gas boilers, responsible for the transfer of heat from the combustion gases to the water or heating fluid, without mixing the two substances.

What functions do the burners serve in natural gas boilers?

Burners in natural gas boilers are essential for initiating the combustion process. They mix the natural gas with air and ignite it, creating the heat necessary for the boiler’s operation.

In a gas boiler system, what is the purpose of the control unit?

The control unit in a gas boiler system manages overall boiler operation. It ensures the system heats water to the desired temperature, maintains efficiency, and conserves energy by adjusting the burner operation and modulating the flow rate.

How does the safety valve contribute to the proper functioning of a gas boiler?

A safety valve is crucial for preventing excessive pressure build-up within the boiler, which could lead to potential damage or hazardous conditions. By releasing pressure when necessary, it ensures the boiler systems operate within safe parameters.